| Plastic | Plastic injection parts | Plastic material | ABS /PC /TPU/PP/PE/Nylon/POM/PMMA etc |

| Plastic surface finish | Polishing finish,Texture Finish,Glossy Finish,Painting,Slik print,Rubber Painting etc | Certification | ISO9001:2015, ISO13685,IATF16949 |

| Max Produce Size | 1500x1500x1000mm | Color | RAL / PANTONE |

| Design software | Solidworks, Pro-E, UG, CAD, Rhino etc. | Drawing format | IGES, STEP, AutoCAD, Solidworks, STL, PTC Creo, DWG, PDF, etc.. |

| Mold life | 300,000 to 1,000,000 shots | Product weight | 1g-15kgs |

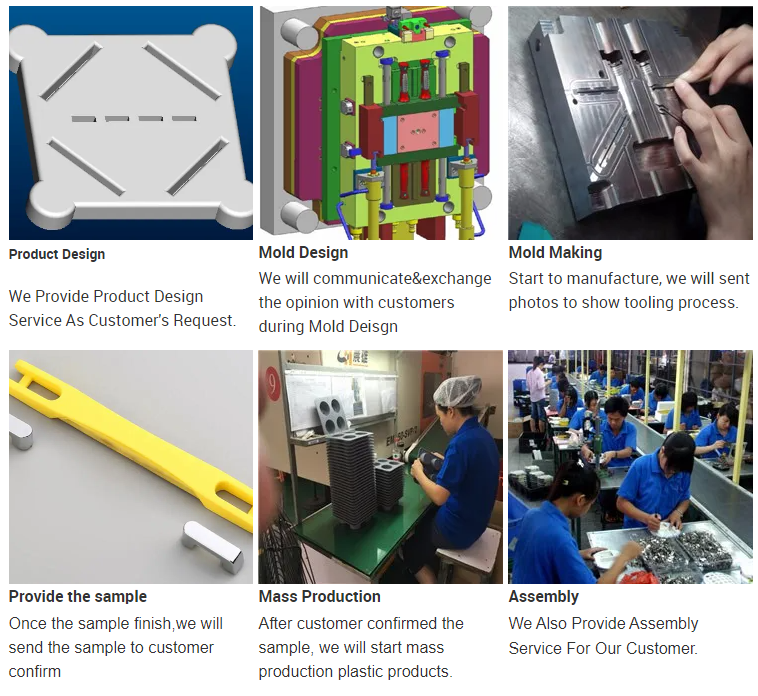

RFQ: Q1. ARE YOU A FACTORY OR TRADE COMPANY? --Yes, we are a factory, is a one-stop source forall of your customized products. Q2. CAN YOU HELP ME TO DESIGN MY PRODUCT OR IMPROVE MY DESIGN? --Yes, we have a professional design team to help our customer to create their product or improve their design. We need sufficient communication before design to understand your intention. Q3. HOW TO GET A QUOTATION? --Please send us drawings in IGS,DWG, STEP file, etc. Detailed PDF together wil e great. If you have any requirements, please remark. Wecould provide professional advice for your refer-ence. The sample will be okay if no drawings, theen we will build and send you a clear and concise drawing to confirm before the quote. Meanwhile, we will keep our promise about the confidentiality of the drawing. Q4. CAN YOU DO ASSEMBLY AND CUSTOMIZED PACKAGE? --Yes, we have assmebly line, so you can finish the production line of your product as the last step in our factory. Q5. DO YOU PROVIDE FREE SAMPLE? --Yes we offer free sample but do not afford the shipping cost. Q6. WHO OWNS THE MOLD IF I PAY FOR MOLD FEE?--You paid the mould so it all belong to you forever, and we will give lifelong maintenance. If necessary, you can take this mould back. Q7. HOW CAN YOU KEEP YOUR PROMISE ABOUT QUALITY? --We have an independent quality department to check every step by IQC, IPQC, OQC.If there are any defective items we willl take corrective action to ensure the elimination of the root cause of defects. When you get the goods and find there is a defect after check. We promise to accept your asked return at our cost or provide replacement free. Q8. WHEN WILL YOU SHIP THE DIE CASTING UNITS OR THE T1SAMPLE? --Normall,it takes 18-35 business days for the mold, then we will send you T1 sample for approval. And 9-18 business days for mass production.it is based on quanitty. Q9. HOW TO SHIP? --The free sample or small order is usually sent by TNT,FEDEX,UPS,etc,and the big order is sent by air or sea after clients confirm. Plastic Injection Part ,Custom Design Plastic products,Plastic Molding Injection,Plastic Shell

RFQ: Q1. ARE YOU A FACTORY OR TRADE COMPANY? --Yes, we are a factory, is a one-stop source forall of your customized products. Q2. CAN YOU HELP ME TO DESIGN MY PRODUCT OR IMPROVE MY DESIGN? --Yes, we have a professional design team to help our customer to create their product or improve their design. We need sufficient communication before design to understand your intention. Q3. HOW TO GET A QUOTATION? --Please send us drawings in IGS,DWG, STEP file, etc. Detailed PDF together wil e great. If you have any requirements, please remark. Wecould provide professional advice for your refer-ence. The sample will be okay if no drawings, theen we will build and send you a clear and concise drawing to confirm before the quote. Meanwhile, we will keep our promise about the confidentiality of the drawing. Q4. CAN YOU DO ASSEMBLY AND CUSTOMIZED PACKAGE? --Yes, we have assmebly line, so you can finish the production line of your product as the last step in our factory. Q5. DO YOU PROVIDE FREE SAMPLE? --Yes we offer free sample but do not afford the shipping cost. Q6. WHO OWNS THE MOLD IF I PAY FOR MOLD FEE?--You paid the mould so it all belong to you forever, and we will give lifelong maintenance. If necessary, you can take this mould back. Q7. HOW CAN YOU KEEP YOUR PROMISE ABOUT QUALITY? --We have an independent quality department to check every step by IQC, IPQC, OQC.If there are any defective items we willl take corrective action to ensure the elimination of the root cause of defects. When you get the goods and find there is a defect after check. We promise to accept your asked return at our cost or provide replacement free. Q8. WHEN WILL YOU SHIP THE DIE CASTING UNITS OR THE T1SAMPLE? --Normall,it takes 18-35 business days for the mold, then we will send you T1 sample for approval. And 9-18 business days for mass production.it is based on quanitty. Q9. HOW TO SHIP? --The free sample or small order is usually sent by TNT,FEDEX,UPS,etc,and the big order is sent by air or sea after clients confirm. Plastic Injection Part ,Custom Design Plastic products,Plastic Molding Injection,Plastic Shell