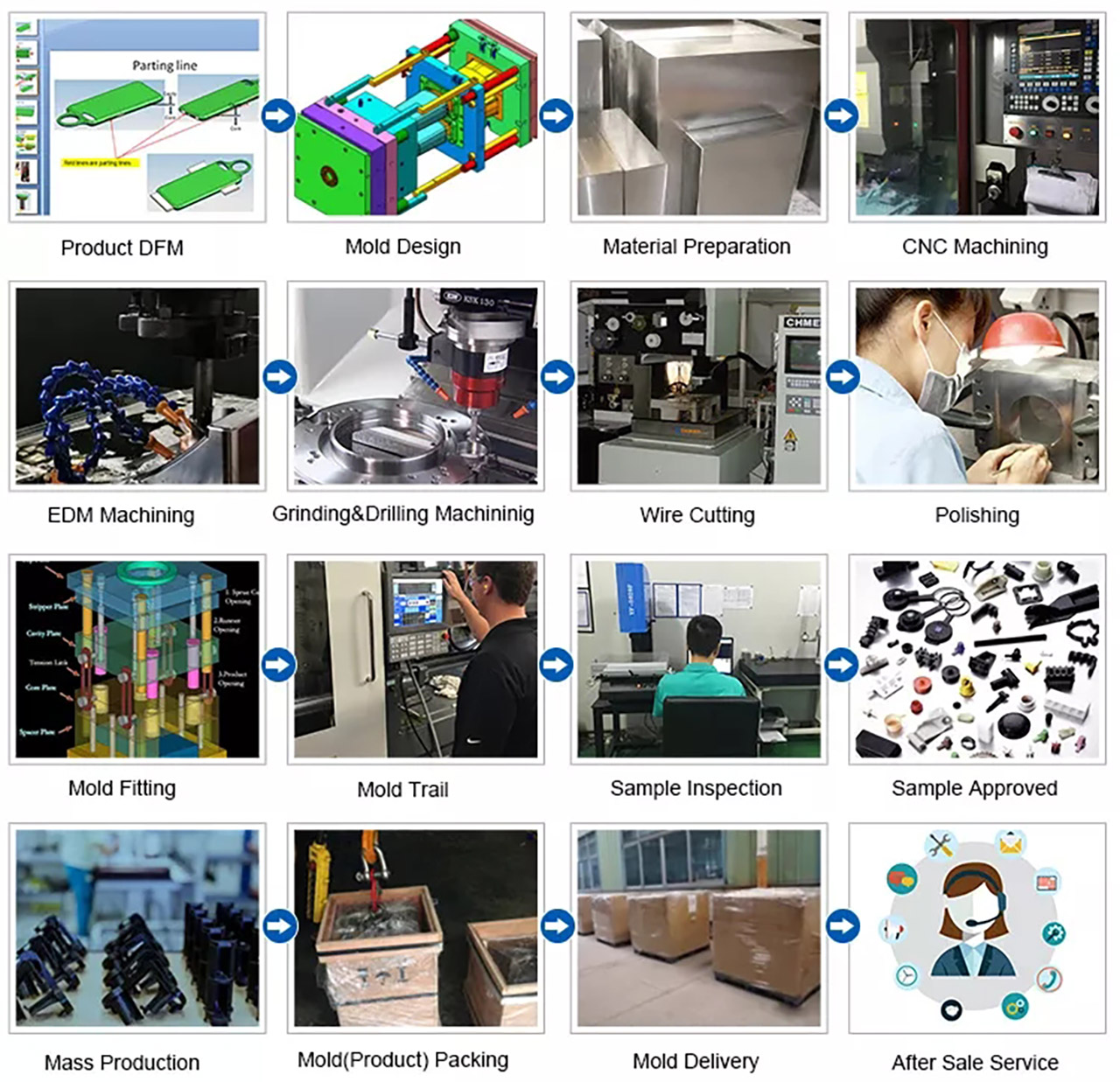

| Prodcuts | One-Stop Service Plastic injection mold factory |

| Material | PA, POM, ABS, PP, PET, PC, PE, HDPE, PA66+GF, PVC, TPFE.... |

| Color | Depends on customer's requirements. |

| Support Software: | Pro-E , UGS , SolidWorks ,AutoCAD |

| Soft ware | CAD/IGS /STEP/STP /PDF |

| A surface request | glossy ,texture |

| Mold life | 50,000-3000,000 times |

| Sample : | Free sample ! |

| Delivery time : | 15 days production, if opening mould, plus 15-20 days. |

| MIN Quantity: | 1000pcs |

| Package | Carton and Pallet , exact part with package every pc |

Quality Control: 1) Checking the raw material after they reach our factory------- Incoming quality control ( IQC) 2) Checking the details before the production line operated 3) Have full inspection and routing inspection during mass production---In process quality control(IPQC) 4) Checking the goods after they are finished---- Final quality control(FQC) 5) Checking the goods after they are finished-----Outgoing quality control(OQC)