Shenzhen Zhongda Plastic Mould Co., Ltd., a leading manufacturer of plastic injection molds, has announced the launch of its new and innovative hot runner system that promises to revolutionize the plastic injection molding industry.

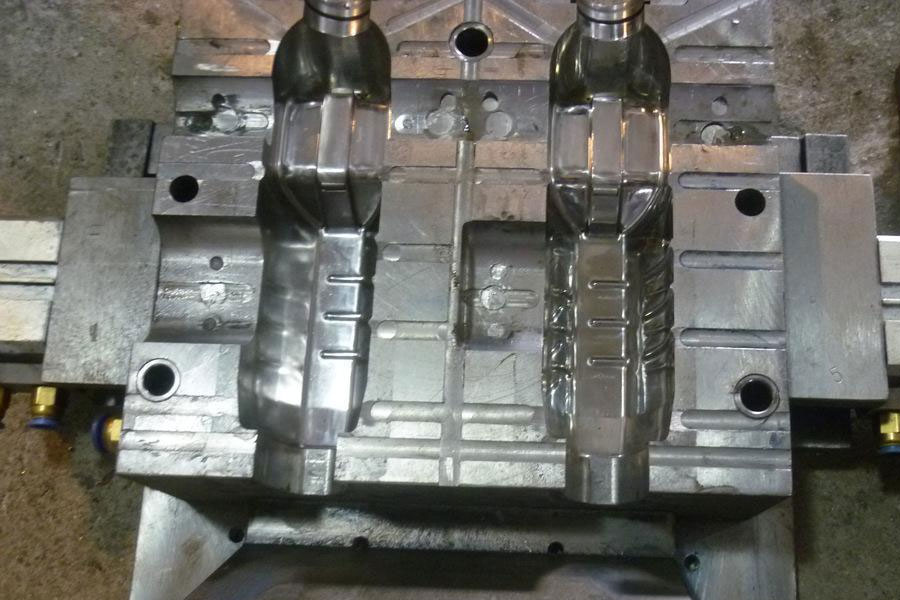

The new hot runner system is an assembly of heated components that are used in plastic injection molds to inject molten plastic into the cavities of the mold. These cavities are the part of the mold that is shaped like the parts to be produced. The system is designed to eliminate the use of sprues, runners, and gates, which are common in traditional injection molding processes. Sprues are channels through which molten plastic flows into the mold, runners are channels that connect the sprue to the cavities, and gates are the small openings through which the plastic enters the cavities.

The new hot runner system from Shenzhen Zhongda Plastic Mould Co., Ltd. is more efficient and cost-effective than traditional injection molding methods because it eliminates the need for sprues, runners, and gates. This means that the system requires less plastic material, reduces waste, and produces better-quality finish products. The system is also more environmentally friendly because it reduces the amount of plastic waste that is generated during the injection molding process.

With more than a decade of experience in the plastic injection molding industry, Shenzhen Zhongda Plastic Mould Co., Ltd. is a one-stop solution manufacturer that offers a range of services, including product design, mold design, mold making, injection molding, and assembly products. The company's state-of-the-art manufacturing facility is located in the Shenzhen Economic Development Zone, which is known for its high-tech industrial parks.

Shenzhen Zhongda Plastic Mould Co., Ltd. uses the latest technology and equipment to manufacture its hot runner systems, ensuring that they meet the highest quality standards. The company's team of experienced engineers and technicians work closely with clients to understand their needs and develop customized solutions that meet their specific requirements.

The hot runner system from Shenzhen Zhongda Plastic Mould Co., Ltd. is suitable for a wide range of applications, including automotive, electronics, consumer products, and medical devices. It is ideal for producing parts that require high precision, accuracy, and consistency, such as gears, connectors, and housings.

According to the company's spokesperson, "We are thrilled to introduce our new hot runner system, which offers significant advantages over traditional injection molding methods. Our system is more efficient, cost-effective, and environmentally friendly than conventional methods. We believe that our customers will benefit greatly from this technology, and we are committed to providing them with the highest quality products and services."

Shenzhen Zhongda Plastic Mould Co., Ltd. is dedicated to staying at the forefront of the plastic injection molding industry by investing in research and development and state-of-the-art manufacturing equipment. The company's commitment to innovation and excellence has earned it a reputation as a leading manufacturer of high-quality injection molds.

In conclusion, the launch of the innovative hot runner system from Shenzhen Zhongda Plastic Mould Co., Ltd. is set to revolutionize the plastic injection molding industry. The system offers significant advantages over traditional injection molding methods, including increased efficiency, cost-effectiveness, and environmental friendliness. With its commitment to quality and innovation, Shenzhen Zhongda Plastic Mould Co., Ltd. is poised to become a leader in the plastic injection molding industry.